The Ultimate Guide to Laser Engraving: A Comprehensive Overview

Laser engraving has become one of the most popular methods for creating intricate designs, patterns, and text on various materials. With its precision and versatility, a laser for engraving offers endless possibilities for both hobbyists and professionals alike. In this article, we will explore everything you need to know about laser engraving, including its benefits, applications, and how to choose the right equipment for your needs.

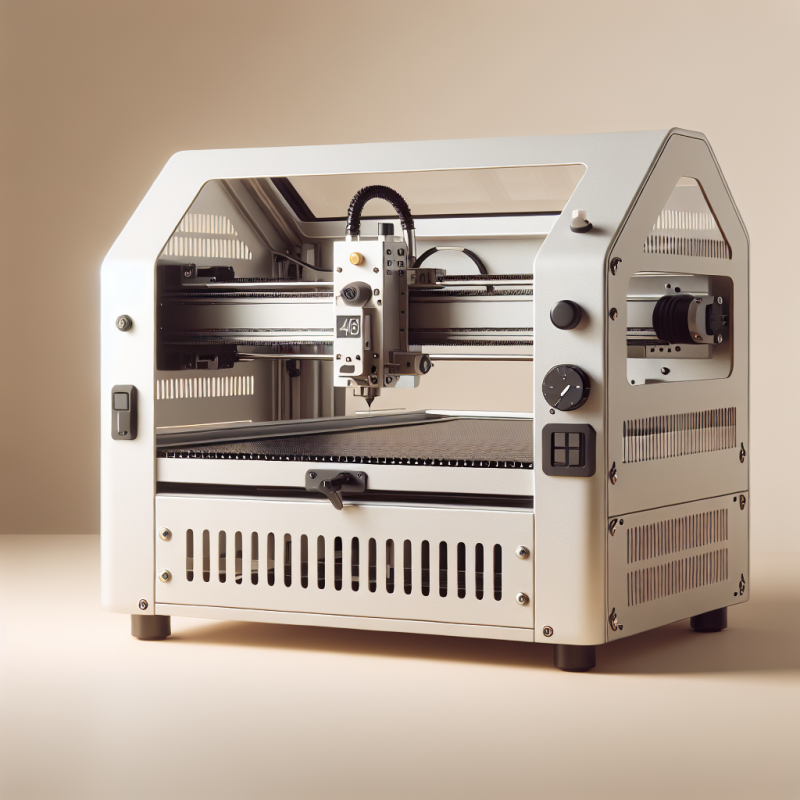

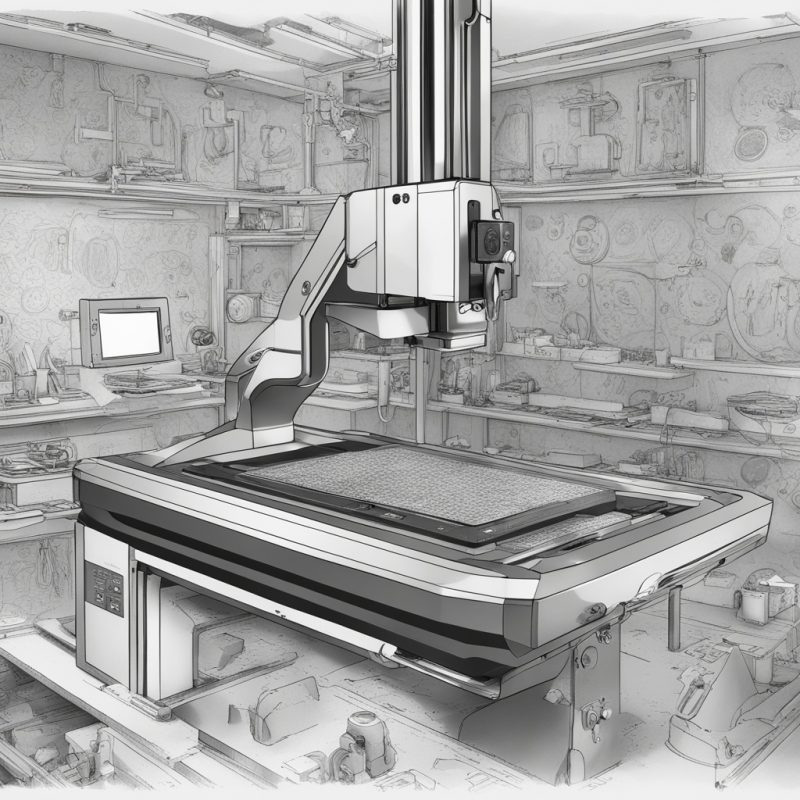

What is a Laser Engraving Machine?

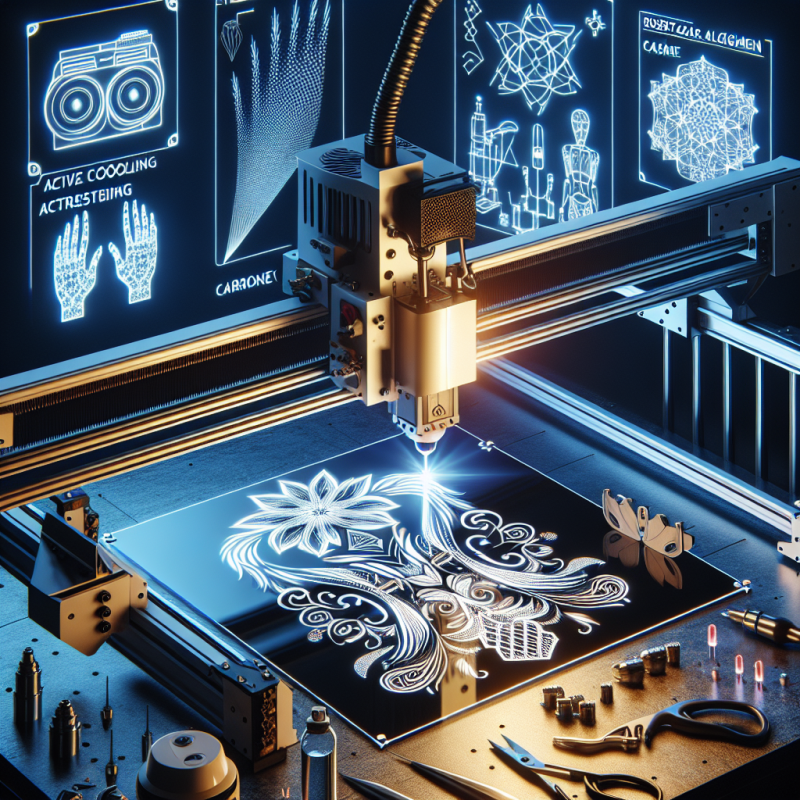

A laser engraving machine uses a focused beam of light to etch or cut materials with incredible precision. Unlike traditional methods that rely on mechanical tools, a laser for engraving produces clean, detailed results without causing damage to the surrounding area. This makes it ideal for working with delicate materials like wood, metal, and even glass.

The machine works by directing a high-powered laser beam at the material’s surface. The laser heats the material, causing it to vaporize or change color, leaving behind a permanent mark. This process is not only faster than traditional engraving methods but also produces sharper details and a more polished finish.

Advantages of Using a Laser for Engraving

There are numerous advantages to using a laser engraving machine over traditional methods:

- Precision: Lasers can create intricate designs with extreme accuracy, even on small surfaces.

- Versatility: A laser for engraving can work with a wide range of materials, including wood, metal, plastic, and glass.

- Speed: Laser engraving is much faster than hand carving or mechanical cutting, making it ideal for large-scale projects.

- No Physical Contact: Unlike traditional tools, lasers do not physically touch the material, reducing the risk of damage or warping.

Applications of Laser Engraving

Laser engraving has a wide range of applications across various industries. Some common uses include:

- Custom Products: Personalized jewelry, name tags, and promotional items can be engraved with unique designs.

- Furniture: Wood laser engraving is popular for creating decorative patterns or initials on furniture pieces.

- Signage: Custom signs and plaques can be produced quickly and efficiently using a laser engraver.

- Artwork: Artists often use laser engraving to create detailed, one-of-a-kind pieces.

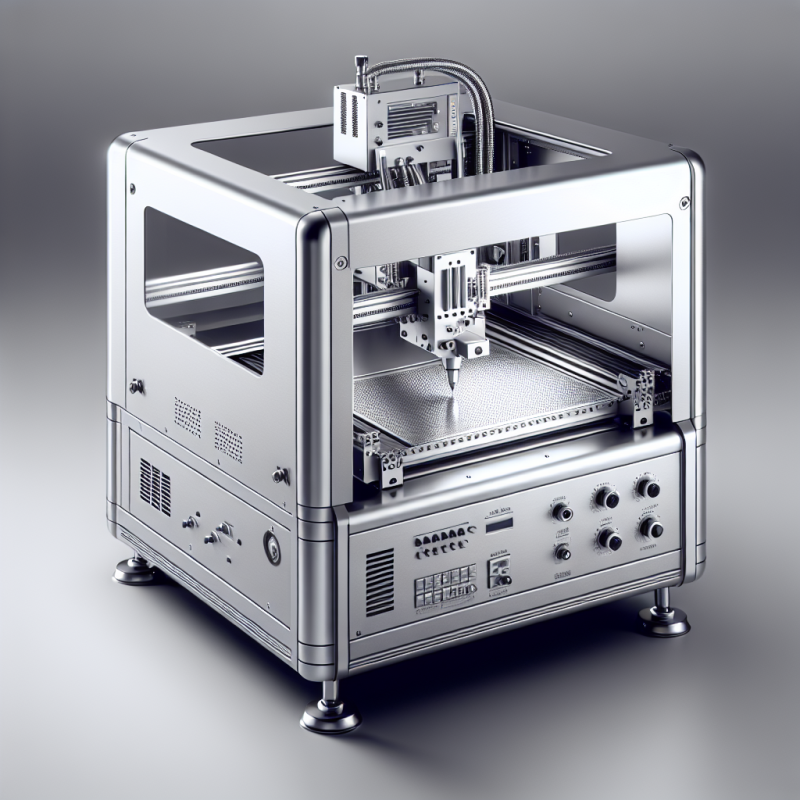

Choosing the Right Laser Engraving Machine

When selecting a laser for engraving, there are several factors to consider:

- Material Compatibility: Ensure the machine can handle the materials you plan to work with.

- Powder or Gas Laser: Powder lasers are typically used for metal, while gas lasers (like CO2) are better for wood and plastic.

- Power Output: Higher power output allows for faster engraving but may be unnecessary for smaller projects.

- Software Compatibility: Look for machines that support popular design software like Adobe Illustrator or CorelDRAW.

Tips for Getting Started with Laser Engraving

If you’re new to laser engraving, here are some tips to help you get started:

- Start Small: Begin with simple designs and gradually work your way up to more complex projects.

- Experiment with Materials: Test different materials to see how they respond to the laser beam.

- Use Protective Gear: Always wear safety goggles and ensure proper ventilation when working with lasers.

- Practice Alignment: Spend time adjusting the machine’s alignment to ensure accurate engraving.

Frequently Asked Questions About Laser Engraving

Laser engraving is a fascinating process, but it can be overwhelming for beginners. Here are answers to some common questions:

1. Can I engrave on all materials?

No, while laser engravers work with many materials, they may not be suitable for certain types of glass or very thick metals. Always check compatibility before starting a project.

2. Is laser engraving safe?

Yes, as long as you follow safety guidelines and use protective gear. Lasers can cause eye damage if exposed directly, so proper precautions are essential.

3. How much does a laser engraver cost?

The cost varies depending on the type and quality of the machine. Entry-level models can be purchased for around $500-$1000, while high-end industrial machines may cost several thousand dollars.

Conclusion

Laser engraving is a versatile and efficient method for creating detailed designs on various materials. With the right equipment, such as a reliable laser for engraving, you can unlock your creative potential and produce professional-quality results. Whether you’re a hobbyist or a professional, investing in a laser engraving machine is sure to enhance your projects and take your craft to the next level.

If you’re ready to dive into the world of laser engraving, consider checking out the collection for high-quality machines that meet your needs. Happy engraving!