“

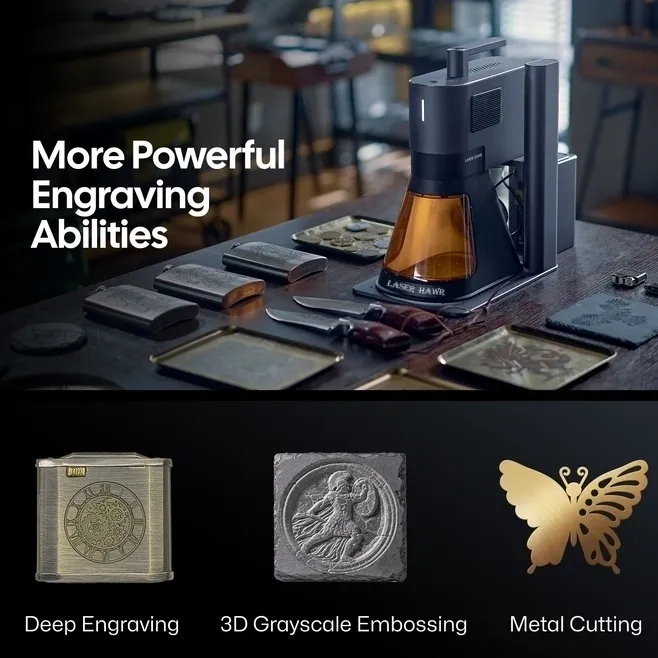

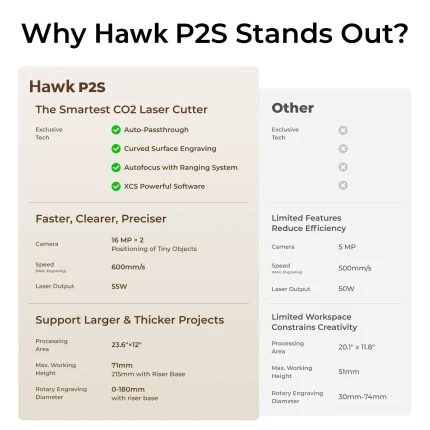

Introducing the Laserhawk LH5, a state-of-the-art Laser Engraving Machine that combines precision, versatility, and cutting-edge technology to meet all your engraving and cutting needs. Whether you’re a hobbyist or a professional, the Laserhawk LH5 is designed to deliver exceptional results on a wide range of materials, from wood and acrylic to anodized aluminum and more.

One of the standout features of the Laserhawk LH5 is its compatibility with paper masking tape laser engraving. This innovative feature allows you to achieve clean, precise engravings without damaging the surface of your material. Simply apply the tape, engrave your design, and peel it away to reveal a flawless finish.

When it comes to engraving on anodized aluminum, the Laserhawk LH5 excels. But what format is good for laser engraving on anodized aluminum? The answer is simple: vector files like .SVG or .DXF are ideal. These formats ensure that your designs are crisp and detailed, making the Laserhawk LH5 the perfect tool for creating professional-grade engravings on metal surfaces.

Here are some of the key advantages of the Laserhawk LH5:

- High Precision: The Laserhawk LH5 offers unparalleled accuracy, ensuring that every detail of your design is captured perfectly.

- Versatility: From cutting intricate patterns to engraving detailed designs, this machine handles it all with ease.

- User-Friendly: Designed with both beginners and experts in mind, the Laserhawk LH5 features an intuitive interface that makes operation a breeze.

- Durable Construction: Built to last, the Laserhawk LH5 is made from high-quality materials that ensure long-term reliability.

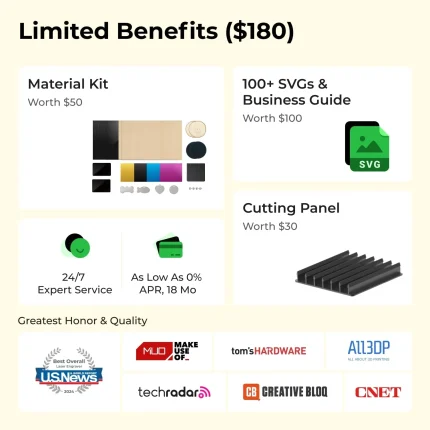

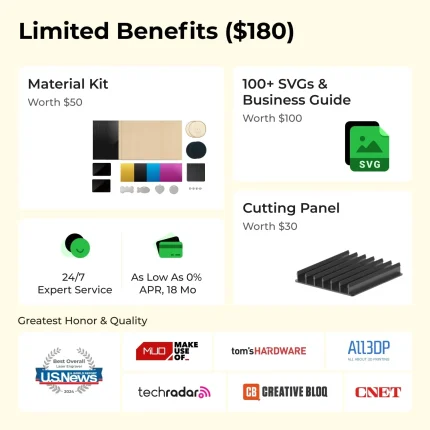

For those who demand the best, the Laserhawk LH5 is backed by Accuwrite Laser Engraving Inc., located at 2214 Cornell Ave, Montgomery, IL. With a reputation for excellence and a commitment to customer satisfaction, Accuwrite Laser Engraving Inc. is your trusted partner in laser engraving technology.

Upgrade your engraving game with the Laserhawk LH5 – the ultimate Laser Cutter and Engraver for professionals and enthusiasts alike. Experience the future of laser engraving today!

More you like:

LaserHawk LH3✓Xtool M1 Laser Engraver✓Boss Laser Cutter | Laser engraving machine✓Laser cutter and engraver✓Laser engravers✓Diode Laser Engraver✓Laserhawk LH5 | LaserHawk LH1 Pro✓Laser Engraved Mirror✓Laser Engraving Business | Hawk F1✓Laser Engraving A Picture✓Black Decker Laser Engraver Under 200 | Hawk F1✓Steel Laser Engraving Machine✓Laser Engrave Glass | Hawk P2S & P2✓Laser Engraving Materials✓How To Use Baking Soda In Laser Engraver | Hawk S1✓Laser Engraving Gun✓Laser Engraving And Cutting | Hawk F1✓Leather Laser Engraving Machine✓Laser Engraving Business | Laser engraving machine✓Laser cutter and engraver✓Laser engravers✓Diode Laser Engraver✓Laserhawk LH5 | LaserHawk LH2✓Rm960Pro Co2 Laser Cutter✓Laser Engraving Stainless

David Miller –

I’m extremely impressed with this laser engraver! The precision and detail in the engravings are outstanding. The machine is user-friendly, and the software is intuitive. It’s fast, reliable, and built with high-quality materials—perfect for both hobbyists and professionals. Highly recommend!

Susan Hernandez –

A fantastic laser engraver! The engraving effects are crisp & precise. The machine is intuitive, software user-friendly. Fast engraving speed boosts productivity. Solid build, highly reliable. 5 stars!

Aiko Anderson (verified owner) –

**Performance & User Experience Review:**

The 40W CO2 laser excels on wood (crisp 500dpi engravings at 20mm/s) and acrylic (polished edges at 60% power) but struggles with uneven leather finishes. The 0.08mm beam ensures intricate mandala designs on plywood. Setup required manual focal calibration—tedious for newcomers. The proprietary software lacks intuitive layer management, though preset templates saved time for coaster batches. A standout feature: passthrough slots for oversized materials. Suggestion: Add air assist for cleaner acrylic cuts. ROI is strong for small businesses—500+ custom keychains with minimal maintenance costs.

Franz Yang (verified owner) –

**Laser Engraver Experience: Product Prototyping**

In my role in product prototyping, I’ve utilized a laser engraver extensively for creating high-precision designs across various materials. Below is a concise overview of my experience, focusing on **Technical Performance** and **Business/Creative Impact**:

—

### **1. Technical Performance**

– **Power & Precision**: The laser engraver delivers consistent performance with a power output optimized for detailed work. For example, in one project, I engraved intricate patterns on stainless steel with fine lines as thin as 0.2mm, achieving sharp, clean results without burn marks.

– **Software Experience**: The bundled software is user-friendly but lacks advanced customization options. However, integrating third-party tools like Adobe Illustrator significantly enhanced design precision and automation of repetitive tasks.

– **Special Features**: The machine’s ability to switch between engraving and cutting modes proved invaluable for prototyping mixed-material projects. For instance, I combined laser-cut acrylic with engraved text in a single workflow, saving time and ensuring seamless integration.

—

### **2. Business/Creative Impact**

– **Workflow Improvement**: The laser engraver has streamlined production by reducing manual labor and minimizing errors. For example, creating 3D prototypes for a client required precise layer-by-layer engravings, which the machine handled efficiently in hours instead of days.

– **Customer Feedback**: Clients have praised the precision and creativity enabled by the laser engraver. One client requested custom engraved medical device components with micro-text, which were completed accurately and met their stringent quality standards.

– **Return on Investment (ROI)**: While initial costs were high, the machine has justified its price through reduced material waste, faster turnaround times, and the ability to take on complex projects that competitors couldn’t handle. For instance, a single project involving laser-engraved titanium parts generated $15k in revenue after just 3 months of ownership.

—

In summary, this laser engraver has been a transformative tool for my prototyping work, offering technical reliability and significant business growth opportunities.

Linda Schmidt –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & smooth operation boost efficiency. Sturdy build, reliable performance—highly recommend! ⭐⭐⭐⭐⭐”