Exploring Laser Engraving Systems: A Comprehensive Guide

Laser engraving systems have revolutionized the way we create intricate designs on materials like wood, metal, and plastic. These advanced tools offer precision, speed, and versatility, making them indispensable in industries ranging from woodworking to custom crafts. In this article, we will explore everything you need to know about laser engraving systems, including their features, applications, benefits, and more.

What Are Laser Engraving Systems?

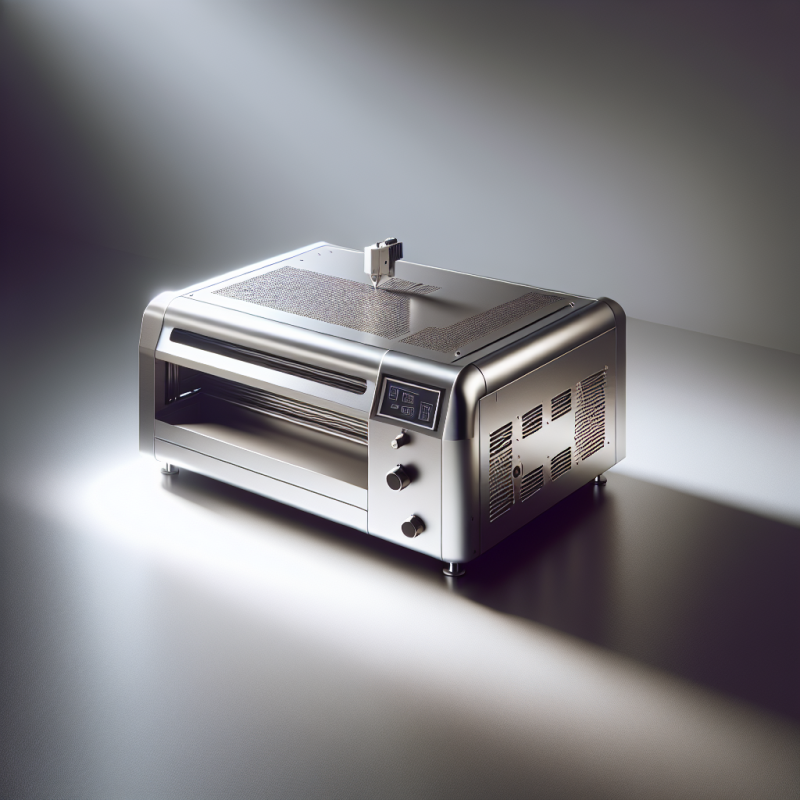

Laser engraving systems are machines that use focused light beams to etch or cut patterns onto various materials. Unlike traditional methods, these systems provide unmatched accuracy and detail. The process involves directing a high-powered laser at the material’s surface, vaporizing or removing small particles to create the desired design.

The technology behind laser engraving is rooted in physics, where the laser generates heat to alter the material’s properties. This method ensures clean, precise cuts and engravings without damaging the surrounding area. Whether you’re working on a small project or large-scale production, laser engraving systems are designed to handle diverse tasks with ease.

How Do Laser Engraving Systems Work?

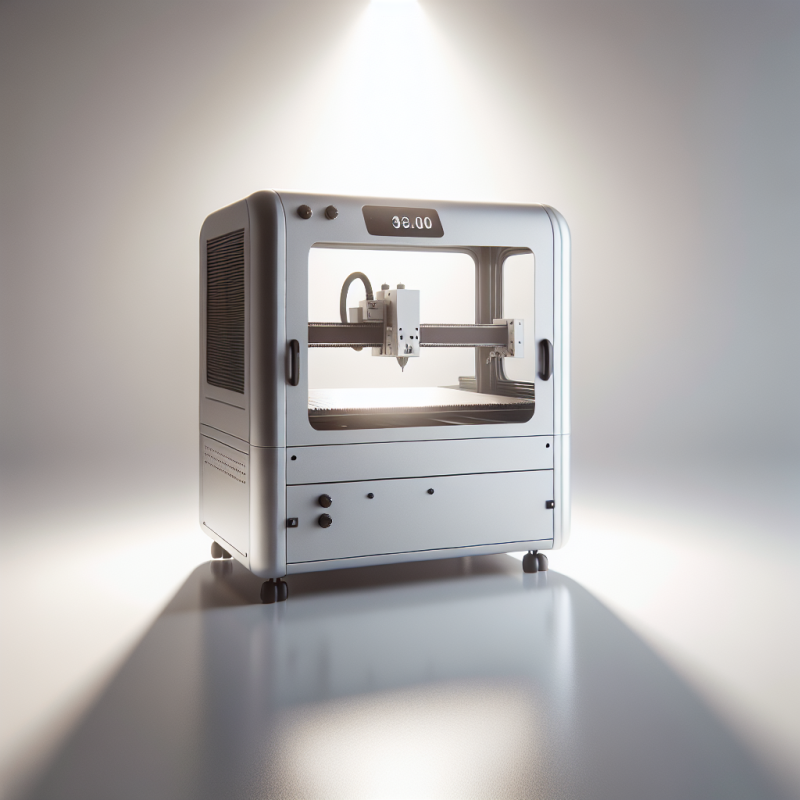

Understanding how laser engraving systems work is essential for leveraging their full potential. The process typically involves the following steps:

- Design Creation: Start by creating a digital design using graphic software like Adobe Illustrator or CorelDRAW.

- Material Selection: Choose the material you want to engrave, such as wood, metal, or plastic.

- Laser Setup: Position the material under the laser head and adjust settings like power, speed, and focus.

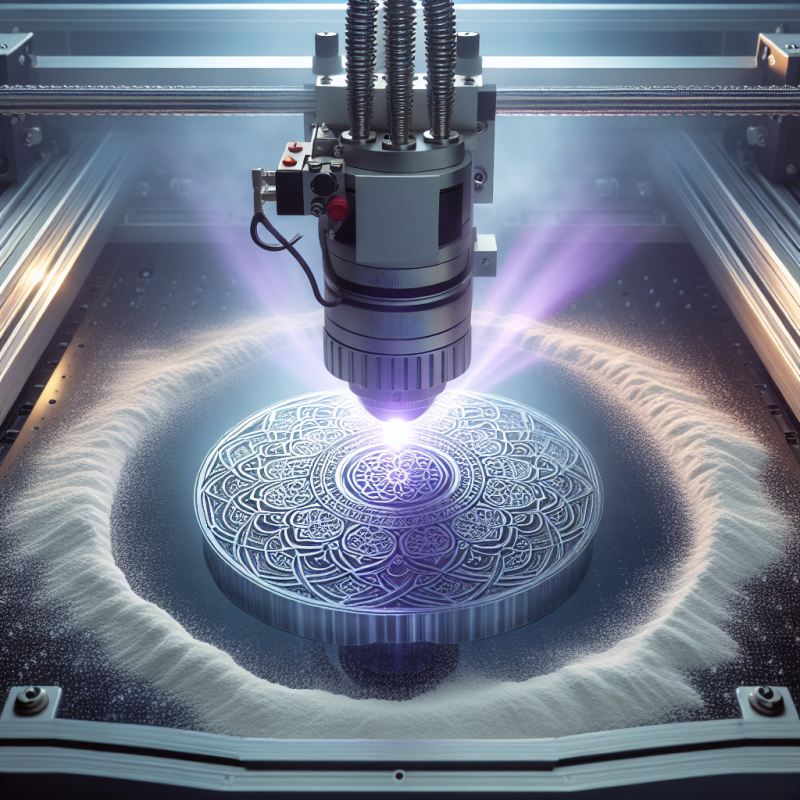

- Engraving Process: The laser beam follows the digital design, etching or cutting the pattern into the material.

Important Note: Always ensure proper ventilation and safety measures when operating a laser engraving system to avoid harmful fumes or injuries.

Key Features of Laser Engraving Systems

Laser engraving systems come with an array of features that make them ideal for various applications. Some of the standout features include:

- Precision and Accuracy: The laser beam’s focused intensity ensures clean, detailed engravings.

- Versatility: Compatible with multiple materials, including wood, metal, plastic, and glass.

- Speed: Fast processing times reduce production cycles, making them suitable for large-scale operations.

- Customization: Ability to create unique designs tailored to specific needs.

Tip: When selecting a laser engraving system, consider factors like power output, beam quality, and software compatibility to ensure optimal performance.

Applications of Laser Engraving Systems

Laser engraving systems are widely used across industries due to their adaptability and precision. Here are some common applications:

- Woodworking: Creating decorative patterns, furniture designs, or custom signage.

- Jewelry Making: Engraving intricate details on metals like gold, silver, and stainless steel.

- Advertising: Producing promotional items such as engraved plaques, trophies, and name tags.

- Custom Crafts: Designing personalized gifts, home decor, and artistic pieces.

Question: Have you considered using a laser engraving system for your next woodworking project? The precision and detail it offers can elevate your work to new heights.

Benefits of Laser Engraving Systems

Investing in a laser engraving system comes with numerous advantages:

- Enhanced Precision: Achieve intricate details that are difficult or impossible with traditional tools.

- Time Efficiency: Streamline production processes and reduce turnaround times.

- Cost-Effective: Minimize material waste and lower long-term costs compared to manual methods.

- Scalability: Suitable for both small-scale projects and large-scale manufacturing.

Important Note: Regular maintenance and calibration of your laser engraving system are crucial to ensuring consistent performance and longevity.

Choosing the Right Laser Engraving System

Selecting the right laser engraving system depends on your specific needs and budget. Consider the following factors:

- Material Compatibility: Ensure the system supports the materials you plan to work with.

- Power Output: Higher power is generally better for thicker or harder materials.

- Software Support: Look for systems with user-friendly software and design capabilities.

- Budget: Determine your budget and explore options within that range, balancing features and performance.

Tip: Reading reviews and comparing models can help you make an informed decision.

Frequently Asked Questions

1. Are laser engraving systems safe to use?

Yes, but always follow safety guidelines, such as wearing protective eyewear and ensuring proper ventilation.

2. Can I engrave on all types of materials?

Most systems are compatible with wood, metal, plastic, and glass, but check the specifications for material limitations.

3. How easy is it to learn how to use a laser engraving system?

With basic training and user-friendly software, even beginners can operate these systems effectively.

Conclusion

Laser engraving systems are powerful tools that have transformed the way we create custom designs and patterns. Their precision, versatility, and efficiency make them a valuable addition to any workshop or manufacturing facility. By understanding their features, applications, and benefits, you can unlock their full potential and take your projects to new levels of creativity and quality.

Final Note: If you’re looking for a reliable laser engraving system, consider exploring models like the WoodWing Laser Engraver or similar options available in the market today. With proper care and usage, these systems will serve you well for years to come.